Three Sizes Available

Mission Industires analog position indicators are available in three sizes to be mounted in handwheel centers.

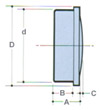

Indicator Housing Dimensions

| Size | Dial Face Diameter | A | B | C | d | D |

| Small | 1.81 | 1.09 | .79 | .07 | 2.16 | 2.32 | |

| Medium | 3.12 | 1.21 | .91 | .04 | 3.45 | 3.61 | |

| Large | 4.50 | 1.21 | .91 | .10 | 4.83 | 4.99 |

Indicator Transmission Ratios

| Size | Available Ratios |

| Small |

4:1 3:1 2:1 1:2 1:3 1:4 1:5 1:6 1:8 1:10 1:12 1:15 1:16 1:18 1:20 1:24 1:25 1:30 1:36 1:40 1:48 1:60 1:64 1:72 1:80 1:96 1:100 1:120 |

| Medium and Large |

4:1 3:1 2:1 1:2 1:3 1:4 1:5 1:6 1:8 1:10 1:12 1:15 1:16 1:18 1:20 1:24 1:25 1:30 1:36 1:40 1:48 1:50 1:60 1:64 1:72 1:80 1:96 1:100 1:120 1:150 1:160 1:180 1:200 1:240 1:250 1:300 1:320 1:360 1:400 1:450 1:500 1:600 1:648 1:720 1:750 1:900 1:1080 |

Construction

| Lexan housing and lens | lightweight and resilient, will not rust or corrode. |

| Stainless steel ball bearing | provides a precise smooth rolling mounting for the gear cluster frame. |

| Injection molded Delrin gear cluster frame | improved weight reduction and reliability. |

| Hobbed brass gears | insures positive, long lasting drive train. |

Four Types of Housing Construction Available

| MODEL | DESCRIPTION | CUSTOMER SHAFT RPM REQUIREMENTS |

| Standard | Dustproof | None |

| Sealed | Hot and Cold Water Sealed | None |

| Mineral Oil Filled | Prevents misting of lens, dampens dial from machine vibrations | Less than 30 RPM |

| Sealed with Silicon | Prevents misting of lens and is waterproof | None |

Installation

Self-contained simplicity. Nothing to hookup, no complicated circuits to run, no electronics to install. Easy mounting: zero the instrument, zero the input shaft, set the instrument into the handwheel cavity and lightly tighten the screw.

Mission Industries, Inc.